A Superior Energy Services Company

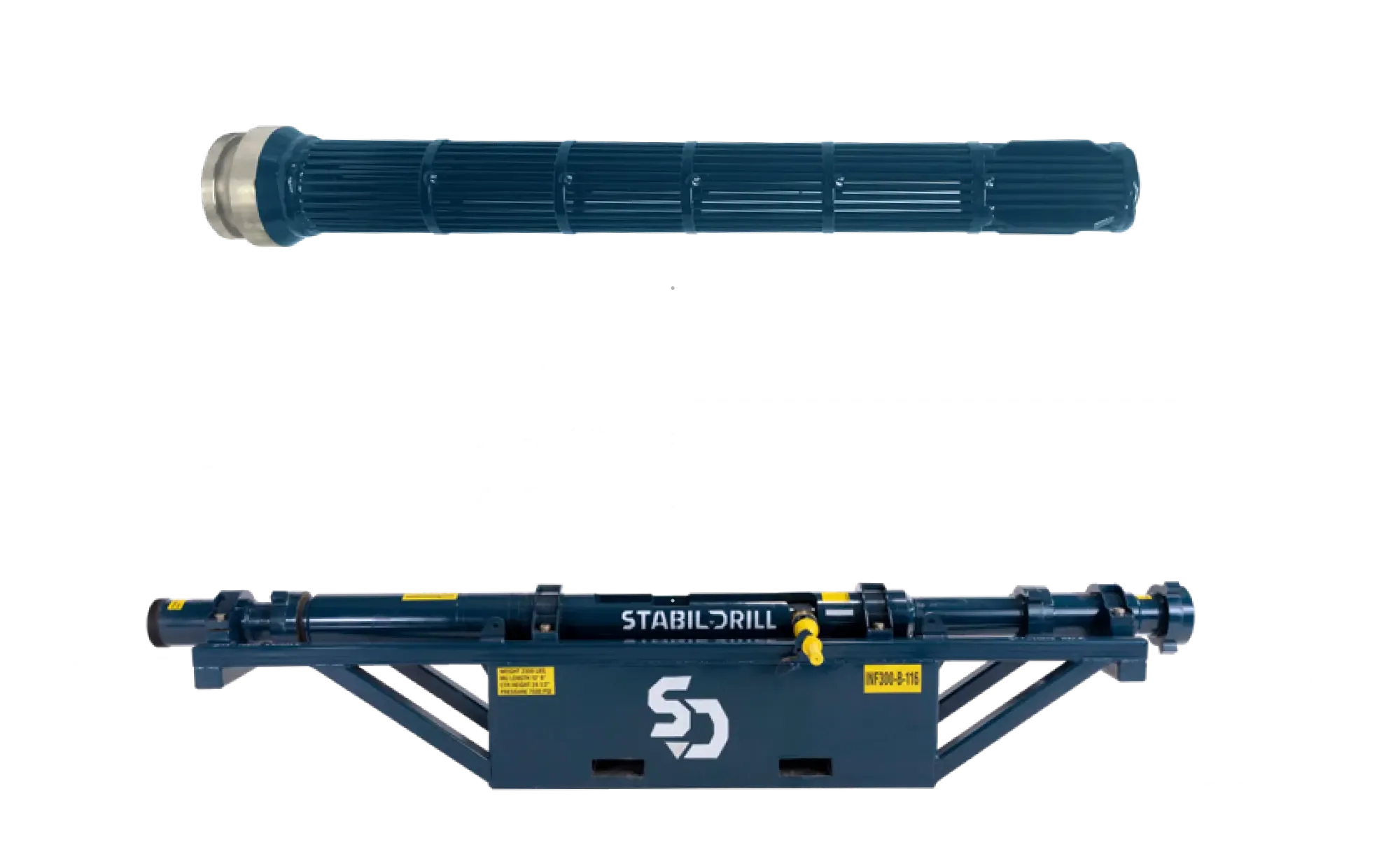

Friction can be a drag on the performance your oilfield drilling operation. With a high-frequency pulse signature, the SD-700 creates an axial oscillation along the drill string to unlock operational performance. Extremely MWD-compatible, SD-700 increases steering efficiency, practical reach, and rate of penetration.

Developed in partnership with Don Mashburn, the SD-700 delivers hyper-efficient flow, fast filter changes, and turnkey field deployment. Its bolt-action design eliminates sledgehammer hazards and cuts maintenance time by 90%-keeping your crews safer, filters cleaner, and operations moving.

| Technical Specifications | |

| Working Pressure | 7500 Max PSI |

|---|---|

| Make Up Length | 12'-9" |

| Center Connection - Standard | 24-1/2" |

| Center Connection - Short | 6-1/2" |

| Unit Weight | 2350 LBS |

| End Connections | 5" 1502 or 5" 1002 |

| Pickup/Handling Points | Forklift Pockets, Padeyes/Slings, Open Tubing for Chain/Sling Lifting |

| Filter Screen | 24" Tapered slot width: .100" @ Top - .065" @ Bottom |

Streamline field operations and minimize Non-Productive Time (NPT) with a unit that reduces 30–45 minute filter changes to less than a minute. The SD-700’s innovative bolt action means no sledgehammers, improved safety, less NPT and lower maintenance costs. In fact, some customers have seen more than $50,000 in savings.

With inlet and outlet valves, a self-contained skid, a spare filter and all necessary tools included, the SD-700 comes with everything you need. You can customize configuration options for adaptors, crossovers, mounting systems, etc. Choose from two skid designs—one closer to the ground for mudline setups and quick hook-up.

This system delivers superior safety performance when compared to conventional surface inline filtration equipment. Its bolt-action filter access means no swinging a sledgehammer at hammer union bolts, no significant drop hazards and no drill pipe screens. It’s not on the rig floor. its catch tank keeps your work area clean, dry and compliant.

Existing Y-path surface filters are overly complicated and tough on hardware. The SD-700’s linear design offers more efficient flow dynamics than conventional Y-path filter designs. This quantum improvement delivers greater circulatory volume, more resilience in the face of abrupt flow path changes and less washing and tool wear.

Built-in padeyes, forklift pockets and thru tubing make the SD-700 easy to deploy. The unit features a catch tank for overflow. And it's built to last, with rugged construction and round, stainless steel rods that offer strength and fight corrosion. So your filtration system arrives field-ready, and stays that way.

The SD-700 minimizes pump shut-off time for less NPT and more time on the job. With faster filter changes, a straight-line flow path, superior safety and durable construction, no inline filter system does more to improve surface filtration economics. It's a must-have for teams that are serious about economic performance.

See how customers have unlocked success and maximized ROI with our tools.