A Superior Energy Services Company

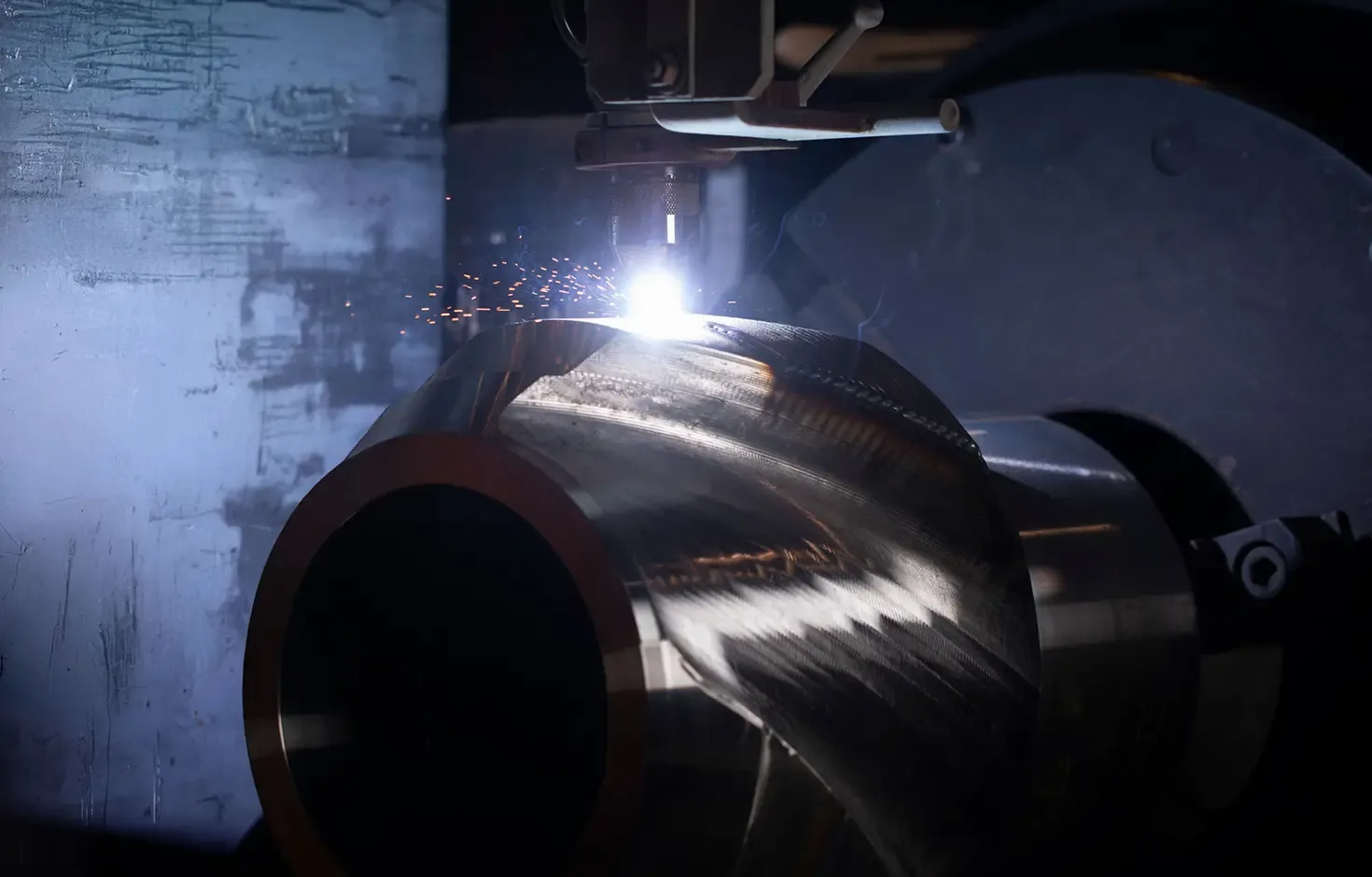

In high-pressure downhole conditions, every second and every inch counts. Our eight specialized hardfacing treatments are engineered to extend tool life, optimize run time, and boost ROI—so you can reach your goals, faster.

From tungsten carbide overlays to advanced abrasion-resistant alloys, our portfolio of hardfacing treatments gives you the right wear protection for the job. Beyond your standard hardfacing processes, we also offer Plasma Transfer Arc (PTA) hardfacing —a high-precision thermal application that uses a high-energy plasma arc to fuse resilient alloy mixtures directly onto the tool base, delivering an exceptionally tough wear layer.

High-performance wear protection in abrasive formations using 3–4mm tungsten carbide tiles fused in a high-bond nickel matrix. Certified via ultrasonic testing, this hardfacing offers fast, economical repair and is available in multiple thicknesses. Compatible with both 4145 steel and nonmagnetic tools, HF-4000 enhances the durability of stabilizers, motor sleeves, and kick pads.

Engineered for harsh environments, HF-5500 uses MIG-applied tungsten alloy in a multi-layered nickel matrix to shield tool surfaces from extreme abrasion and corrosion. The process applies a cored wire filled with granular tungsten carbide, delivering precision hardfacing for consistent protection. Configurable for both 4145 steel and nonmagnetic tools, HF-5500 extends tool life and performance in aggressive downhole conditions.

A high-carbide, cost-effective hardfacing solution for soft to medium drilling applications. HF-6000 uses crushed tungsten carbide in a nickel alloy matrix to fight downhole wear at lower application temperatures. Designed exclusively for 4145 steel, it’s ideal for maximizing tool life on components where performance and value must align.

Engineered for extreme drilling environments, HF-7000 pairs a thick tungsten carbide layer with a nickel bond layer to deliver high-impact, high-wear protection. Ideal for 4145 steel, it maintains strong corrosion resistance and superior bond strength—ensuring performance and confidence in the most aggressive formations.

A non-magnetic PTA hardbanding solution with 30% spherical tungsten carbide, HB-1000 delivers lasting wear resistance for downhole tools and drill collars where strict magnetic permeability (<1.01μ) is required. Ideal for maintaining tool integrity without compromising directional performance.

A non-magnetic PTA-applied hardfacing with 30% tungsten carbide and 3mm solid tiles for extended tool life. Ideal for stabilizers, motor sleeves, kick pads, and RSS components, HFT-2000 delivers durable wear protection in high-demand downhole environments.

Built for steel-based components, this PTA-applied hardfacing uses 30% tungsten carbide with 3mm solid tiles to extend tool life under stress. Ideal for stabilizers, motor sleeves, and kick pads requiring robust wear protection in abrasive downhole conditions.

For ultimate durability in the most punishing wells, HF-9000 applies a 65% tungsten carbide hardfacing using CNC-controlled precision. This advanced PTA process minimizes heat-affected zones and lowers dilution rates compared to conventional hardfacing—delivering exceptional wear resistance and longer tool life. Ideal for stabilizers, motor sleeves, and kick pads, HF-9000 is the preferred solution for operators facing high-impact, high-friction drilling environments where performance and longevity are non-negotiable.

Our proprietary BlueSteel™ Hardfacing is field-tested and performance-proven to deliver longer runs, less downtime, and lower total cost of drilling. Built from our refined methodology, BlueSteel™ delivers unmatched wear resistance in the harshest drilling environments, helping operators see longer runs, less downtime and lower costs.

Delivers stronger protection with the same amount of material

Creates a tougher and more resilient weld layer

Maximizes tool strength and promotes easier repairs

Ensures reliable, consistent and accurate application