A Superior Energy Services Company

Engineered for drilling efficiency and ROI, Stabil Drill’s Smoothbore™ Eccentric Reamer reduced tripping time and reactive torque—delivering a cleaner, more consistent wellbore for faster, trouble-free casing and measurable cost savings.

Combined saved

dedicated tripping time

Savings realized by

the client

Deviated well depth in

Mississippi Lime formation

Increase wellbore quality, reduce casing time, increase efficiency, and decrease operations cost

Helical blade design to match operating conditions

Stabil Drill Smoothbore™ Eccentric Reamer

Created a smooth wellbore

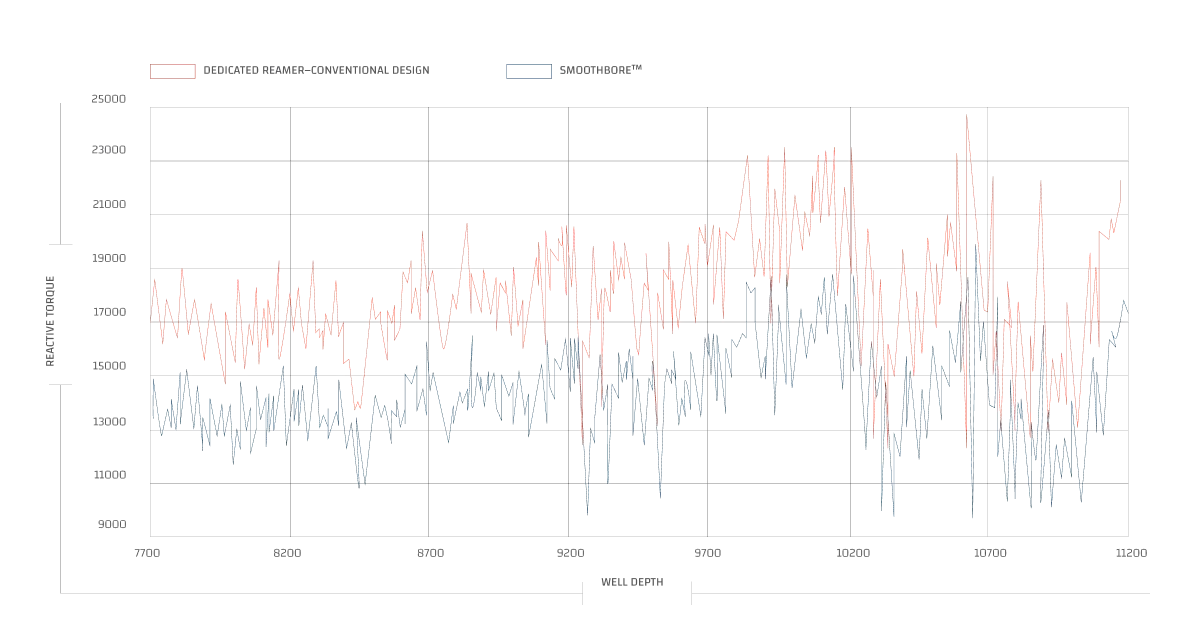

Successfully reamed to TD with minimal torque

Increase wellbore quality and efficiency, all while decreasing operations cost. The client was drilling a deviated well in the Mississippi Lime formation, targeting a total depth of 12,778 feet using a conventional motor BHA. Given the high dogleg severity and directional complexity, maintaining an acceptable drift diameter and achieving a consistently smooth wellbore trajectory were operational priorities. Prior wells in this region required separate reaming runs to correct bore shape—an added phase that increased casing deployment time and total well cost.

The Smoothbore Eccentric Reamer, equipped with helical blade design to match operating conditions.

To increase wellbore quality and eliminate non-productive rig time, the client integrated the Stabil Drill Smoothbore™ Eccentric Reamer into the drill string for a single-run, ream-while-drilling solution. The tool’s engineered helical blade profile was designed to engage the formation progressively, achieving continuous full-gauge contact without overloading the assembly. While the lower section enlarged and conditioned the borehole, the upper blade arrangement actively stabilized the tool—ensuring balanced rotary performance and improved directional control. This design not only produced a smoother wellbore but also significantly reduced reactive torque, supporting more consistent toolface behavior and enhancing downhole efficiency.

Deploying the Smoothbore™ Eccentric Reamer enabled the operator to eliminate a dedicated reamer run entirely. This delivered a time savings of 37 hours across tripping and liner/casing setting activities, translating to a cost reduction of $87,000. Beyond operational efficiency, the tool’s contribution to improved borehole geometry simplified casing installation and reduced mechanical risk. The outcome underscores Stabil Drill’s ability to combine field-proven tool design with engineering-forward thinking to drive measurable performance gains at the rig site.