A Superior Energy Services Company

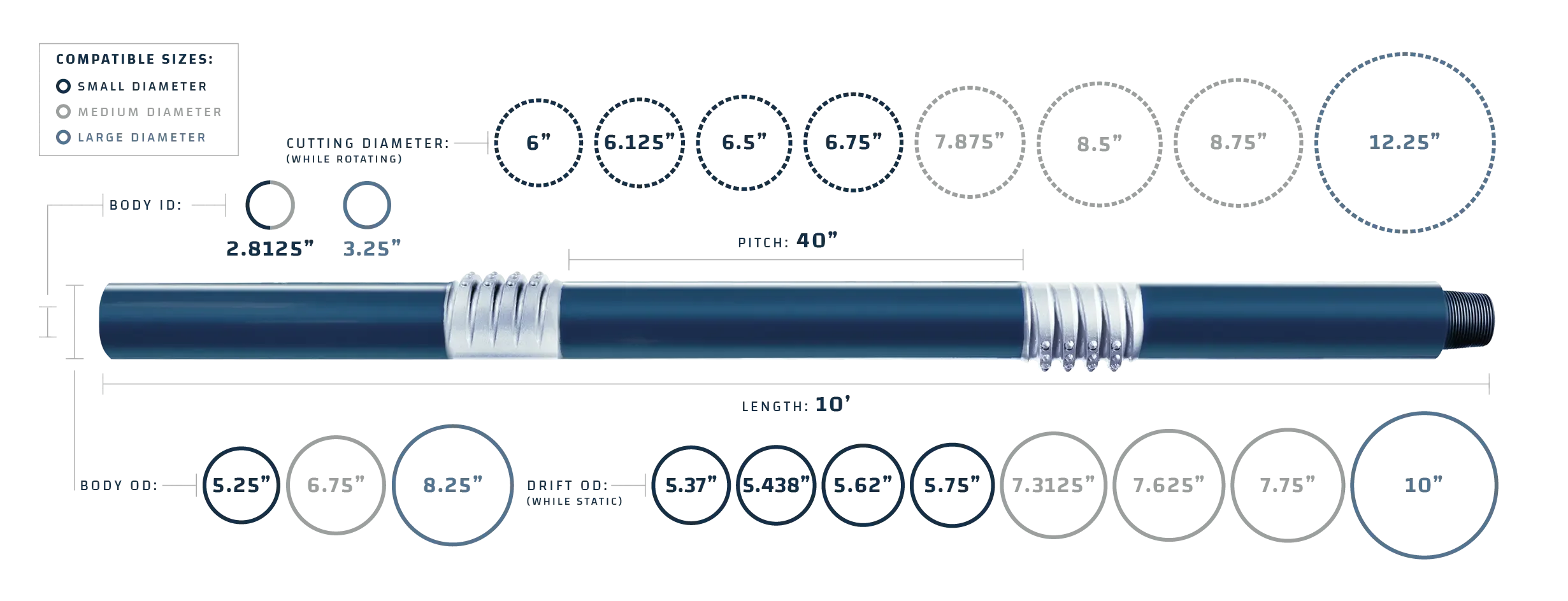

The Smoothbore™ Eccentric Reamer features a patent-pending low-angle spiral blade design that delivers a full cut in a single rotation—streamlining wellbore development and accelerating time to target depth. Running at 240 ft/hour the unit has eliminated as many as two full days, and $100,000 in expenses, from customer drill plans.

The Smoothbore™ Eccentric Reamer’s patent-pending spiral blade design delivers a full cut in a single rotation—accelerating ROP, reducing torque and vibration, and eliminating costly backreaming. Proven to save days and dollars, Smoothbore gets you to target depth faster, with a cleaner, more stable wellbore.

For...

With low-angle spiral blades in a helical orientation, the Smoothbore™ achieves a full cut in a single turn. This innovative design, along with carbide buttons that protect the cutting structure, get you to total depth more quickly.

The Smoothbore’s ream-while-drilling design gives you the ability to pull back smooth without backreaming, while still delivering a high-quality wellbore. Many users report saving an entire day on the trip-out.

The smoothbore’s lower reamer does most of the work. As a result, the tool’s second section, located further up the bottom hole assembly, serves to dynamically stabilize the tool and minimize drill string vibration.

The helical orientation and incremental shear of the Smoothbore™ blade delivers torque reduction of up to 40 percent vs competition. Extensive engineering studies coupled with predictive modeling have been validated through field-testing of the tool.

The Smoothbore eccentric reamer doesn’t inhibit steer-ability. In fact, because of its unique blade design and assembly position, it actually enhances BHA directional capability for greater precision.

See how customers have unlocked success and maximized ROI with our tools.